- English

- 简体中文

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

Why Is Architectural Membrane Reshaping the Future of Large-Span Building Design?

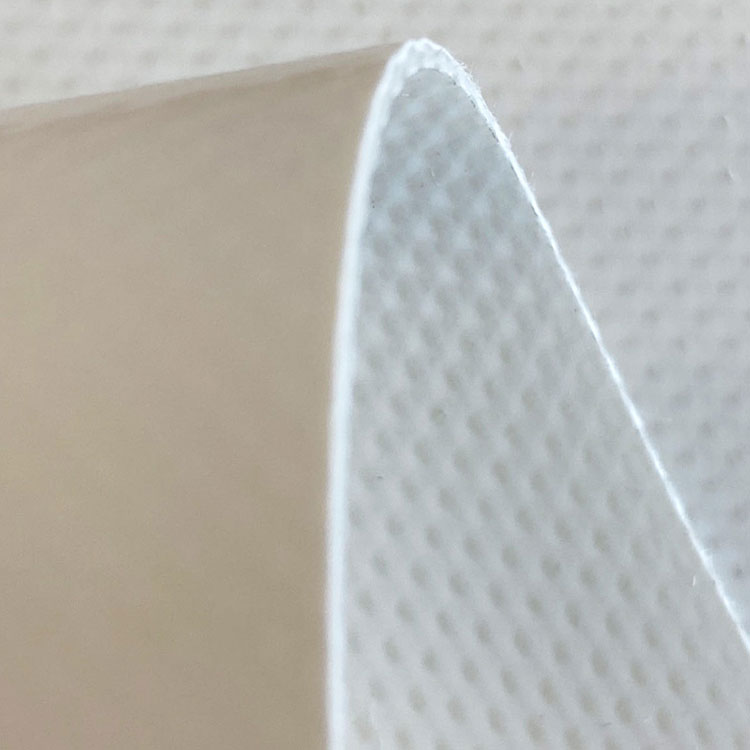

Architectural membrane efers to a high-performance flexible material engineered for building envelopes, roofing systems, shading structures, and innovative public installations. It combines tensile strength, durability, and aesthetic adaptability, making it suitable for airports, stadiums, exhibition halls, commercial canopies, and façade designs.

The purpose of architectural membrane in construction is to provide lightweight yet strong structural coverage that performs efficiently under tension. It enables large-span designs without heavy steel frameworks, reduces overall construction weight, and delivers enhanced light transmission, weather resistance, and visual impact.

Product Parameters Overview

To clarify technical details, the following table presents commonly used parameters in architectural membrane applications:

| Parameter Category | Typical Values / Description |

|---|---|

| Material Composition | PTFE-coated fiberglass, PVC-coated polyester, ETFE film |

| Thickness | 0.18 mm – 1.20 mm depending on model and application |

| Tensile Strength | 4000–8500 N/5 cm (warp) / 3500–8000 N/5 cm (weft) |

| Tear Strength | 400–900 N depending on coating and reinforcement |

| Light Transmission | PTFE: 10%–13%; PVC: 6%–10%; ETFE: up to 90% |

| Temperature Resistance | -70°C to 230°C (material-dependent) |

| Service Life | PTFE membranes: 25–30 years; PVC membranes: 15–20 years; ETFE: 30+ years |

| Fire Rating | Class A or B1 depending on material type |

| Surface Treatment | Dirt-repellent coatings, UV protection, anti-aging finish |

Central Theme of the Article

This article focuses on four key areas:

-

What architectural membrane is and what core values it brings to construction.

-

Why architectural membrane offers unique advantages that traditional materials cannot match.

-

How architectural membrane functions in real-world applications and how it enhances structural performance.

-

How the future of architectural membrane design is evolving, with a concluding highlight of Gaoda Group and a contact invitation.

Why Does Architectural Membrane Stand Out in Structural Engineering?

Why Does Architectural Membrane Excel in Weight-to-Strength Ratio?

Architectural membrane’s primary advantage is its lightweight yet high-strength performance. Compared with traditional roofing materials such as steel plates or concrete tiles, membrane systems use a tensioned framework that minimizes structural load. This allows architects to design expansive spaces without excessive heavy support beams. By reducing dead load, the material supports safer construction, lower foundation requirements, and faster project delivery.

Why Does Light Transmission Make Membrane Structures More Energy Efficient?

Membrane materials, especially PTFE and ETFE, allow natural diffused light to enter indoor spaces. This reduces dependency on artificial lighting and improves visual comfort. When used in public venues, membrane structures create bright and uniform lighting conditions while maintaining heat control and UV protection.

The diffused light also creates a soft, aesthetic glow that architects frequently leverage in stadiums, airports, outdoor canopies, and commercial centers.

Why Do Weather Resistance and Durability Increase Lifespan Value?

Architectural membranes are engineered to withstand ultraviolet radiation, acid rain, wind loads, heavy snow, and extreme temperatures. PTFE-coated fiberglass, for example, is chemically inert and highly resistant to pollution and tearing. ETFE films can endure wind speeds exceeding those tolerated by many rigid materials.

This durability reduces maintenance costs and ensures that buildings retain their structural integrity even in demanding climates.

Why Does Aesthetic Flexibility Make Membrane a Preferred Material for Designers?

Architectural membranes can be molded into various forms: curves, cones, waves, and large-spanning tensile shapes. This versatility supports iconic visual designs often used in modern public architecture. The aesthetic signature of membrane structures is smooth, minimalistic, and futuristic—qualities that align with global architectural trends.

How Does Architectural Membrane Function in Real-World Applications?

How Does the Tension System Create Stability?

Architectural membrane structures rely on tension rather than compression. The membrane is stretched across steel cables or lightweight frames to achieve balanced stress distribution. Once tensioned, the membrane forms a rigid, durable surface capable of withstanding environmental load.

This tension-based mechanism contributes to:

-

Enhanced stability

-

Reduced vibration

-

Efficient load transfer

-

Long-lasting surface tension without deformation

How Does the Material Support Multi-Functional Applications?

Architectural membrane serves multiple functions across various industries:

1. Roofing Systems

Used in stadiums, terminals, arenas, and amphitheaters, membrane roofing creates large, unobstructed spans with natural lighting.

2. Facade Cladding

Membrane façades improve energy efficiency while providing a translucent, modern appearance.

3. Shading Systems

Commercial walkways, transportation hubs, and recreational areas use membranes for effective sun protection.

4. Air-Supported Structures

ETFE cushions create lightweight domes and wall systems capable of handling pressure loads.

How Does Sustainability Factor Into Membrane Usage?

Architectural membrane contributes to sustainable construction through reduced material consumption, long lifespan, recyclable components, and lower energy usage due to natural lighting. These factors align with global green building standards and contribute to environmentally responsible development.

How Does Maintenance Support Long-Term Value?

Membrane surfaces are designed with dirt-repellent coatings to minimize cleaning frequency. PTFE materials, in particular, naturally resist dust buildup. Maintenance typically involves periodic inspection of tension levels, steel components, and surface conditions. Installation and upkeep are straightforward, providing long-term economic benefits.

What Future Trends Shape the Evolution of Architectural Membrane?

What Innovations Are Expected in Material Composition?

Emerging developments focus on coatings with enhanced UV stability, self-cleaning technologies, and improved structural fibers. Nanotechnology integrations may further boost reflective performance and anti-aging properties.

What Role Will Digital Engineering Play?

Future membrane structures will rely heavily on:

-

Computational form-finding

-

Digital load simulations

-

Parametric modeling

-

Smart structural sensors

These tools increase design accuracy and performance forecasting.

What Applications Will Expand in the Coming Decade?

Architectural membrane will see wider adoption in:

-

Eco-friendly sports and entertainment venues

-

Lightweight modular shelters

-

Climate-adaptive shading systems

-

High-transparency façade solutions using ETFE

-

Solar-integrated membranes for energy generation

As urban environments demand more sustainable and visually iconic structures, these applications will continue to grow.

Common Questions About Architectural Membrane

Q1: How long does architectural membrane typically last?

A1: The lifespan depends on the material type. PTFE-coated fiberglass membranes generally last 25–30 years due to their high durability. PVC membranes last around 15–20 years, while ETFE films can exceed 30 years with proper maintenance. Lifespan is also affected by environmental exposure, tensioning accuracy, and surface treatment quality.

Q2: How does architectural membrane perform in extreme weather?

A2: Architectural membrane is engineered to resist wind loads, UV radiation, temperature swings, and snow accumulation. PTFE and ETFE materials maintain stability even in harsh environments. Proper design includes load calculations, tension calibration, and structural reinforcement to ensure consistent performance across all climates.

How Will Architectural Membrane Continue to Influence Building Design?

Architectural membrane has transformed the way architects approach large-span structures by offering lightweight strength, exceptional durability, energy efficiency, and unparalleled design flexibility. Its ability to create visually striking forms while supporting practical performance makes it an essential material for modern and future architectural solutions. With advancements in materials, digital modeling, and sustainable construction methods, the future of architectural membrane is aligned with global trends toward efficiency, aesthetics, and environmental responsibility.

Gaoda Group continues to contribute to the advancement of membrane structure solutions by providing high-quality materials and project support for diverse construction needs. To learn more about architectural membrane products or request professional consultation, contact us.