- English

- 简体中文

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

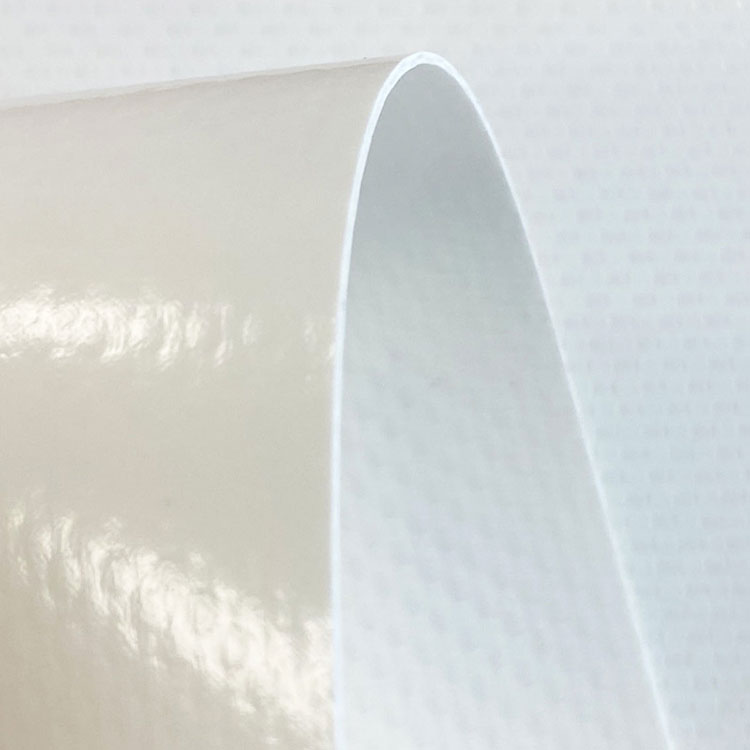

RX5000 General Architectural Membrane

RX5000 General Architectural Membrane is a general type architectural membrane material product suitable for most tensile membrane structures, air dome structures and building warehouse projects.

Send Inquiry

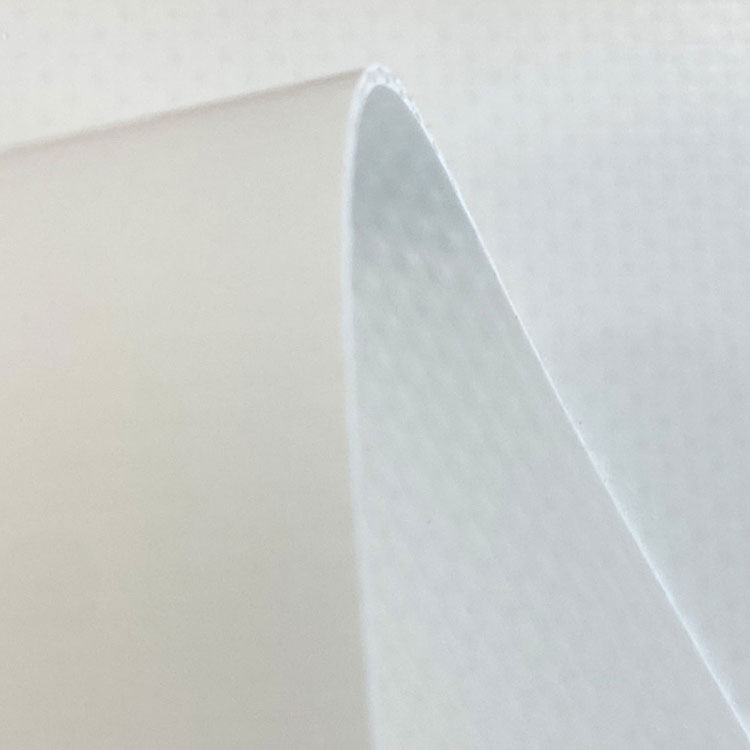

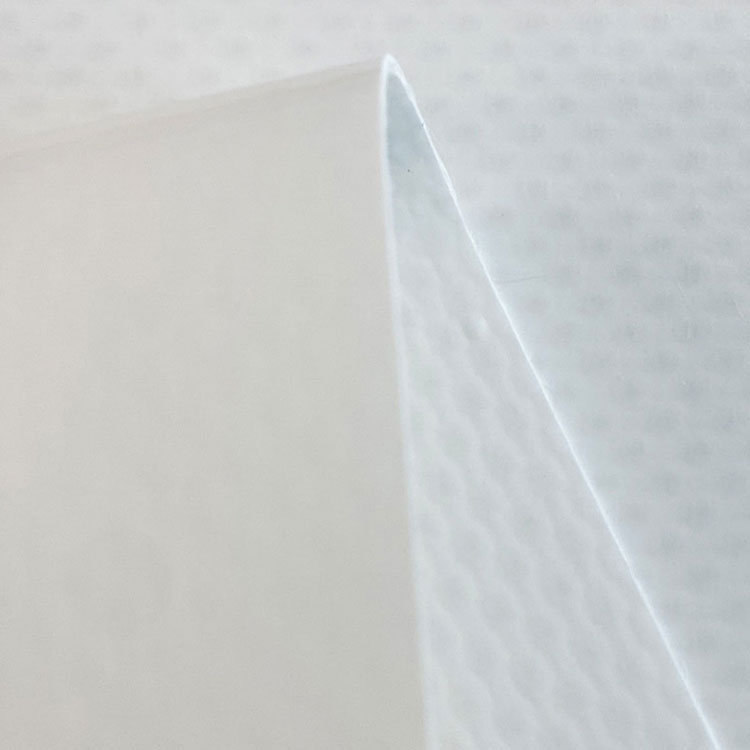

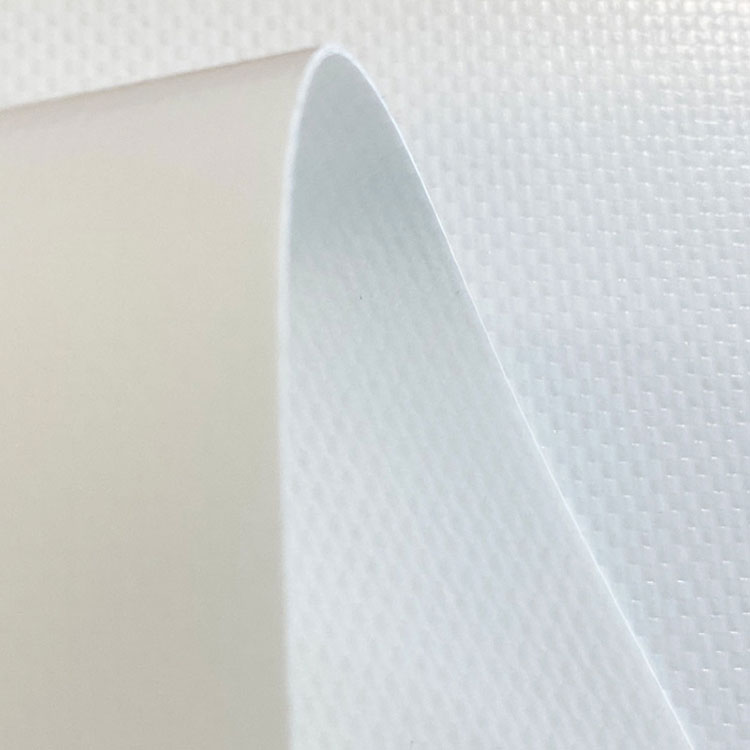

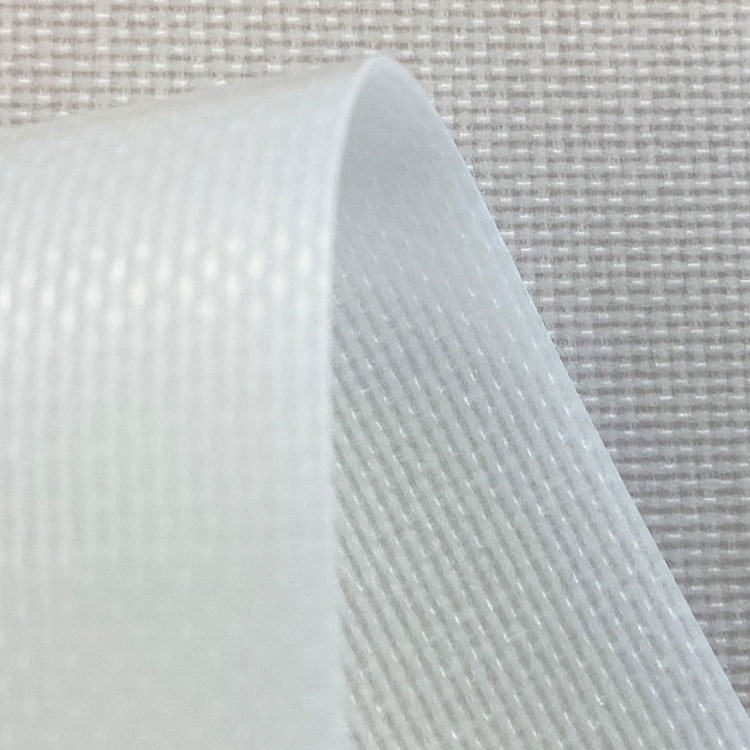

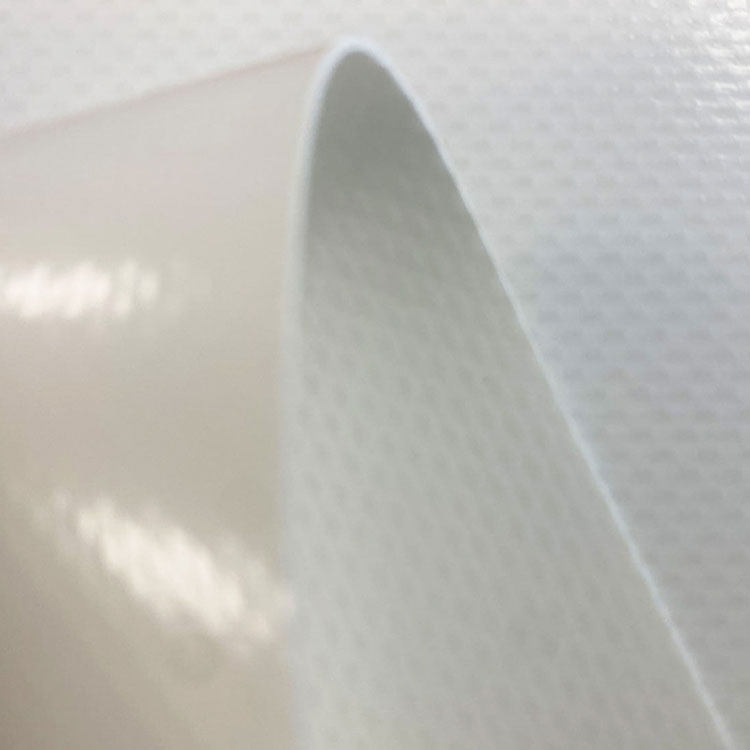

The RX5000 General Architectural Membrane uses Panama woven fabric specifically designed for architectural membrane, which can provide a tensile strength of 5000N/5cm for the material. At the same time, the RX5000 General Architectural Membrane adopts the PVC formula of architectural membrane materials specially developed by Gaoda Group, combined with various surface treatment options such as PVDF and PMMA, to ensure the outdoor weather resistance and service life of the product.

The RX5000 General Architectural Membrane is often used in various specific application scenarios, such as architectural art modeling, sports stadium roofs, umbrella-type building roofs, tensile car sheds, air dome sports venues, air dome coal sheds, air dome biogas storage tanks, small and medium-sized steel beam structure warehouses etc.

| Item | Standard | Unit | Result | |||||

| Weight | GB/T 4669-2008 | g/m2 | 1050 | |||||

| Thickness | GB/T3820-1997 | mm | 0.85 | |||||

| Tensile Strength | DIN53354 | N/5CM | 5000/5000 | |||||

| Tear Strength | DIN53363 | N | 700/700 | |||||

| Adhesion Strength | DIN53357 | N/5CM | 110 | |||||

| Transmittance | FZ/T 01009-2008 | % | 6±3 | |||||

| Temperature | - | ℃ | -40 ~ +70 | |||||

| Flame Retardant | DIN4102 | B1 | ||||||

| Surface Treatment | - | PVDF | ||||||

| Other | Anti-UV, Anti-Mildew | |||||||

|

The above are the technical parameters for the standard configuration of the product. Information contained in this document is based on our general test result and is given in good faith. But we are unable to accept responsibility in respect to factors which are outside our knowledge or control. |

||||||||

| Customization | Anti-Wicking | |||||||

|

Anti-UV Grade≥7 |

||||||||

|

Anti-Extreme Cold -50℃ |

||||||||

|

Anti-Named Fungus&Mildew Type Environmental Friendly Additives |

||||||||

|

Eco–Friendly Treatment REACH, RoHS,6P (EN14372), 3P (EN14372) |

||||||||

|

Surface Treatment PMMA/Acrylic, PVDF, TiO2 Silver Lacquer, Printable Lacquer |

||||||||

|

Flame Retardant Options DIN4102-B1, NFPA701, NF P - M2 GB8624-B1, CA Title 19, FMVSS 302, ASTM E84 DIN4102-B2, GB8624-B2, Basic FR |

||||||||